Do not know how much you know about

seamless steel pipes. The seamless steel pipe is a round, square, rectangular steel, with a hollow part, there is no seam around. Seamless steel pipes are formed by punching steel ingots or solid steel tubes and then hot rolling, cold rolling or cold drawing. A

seamless steel pipe has a hollow cross section and is used as a pipe for transporting a fluid and is lightweight when it has the same flexural strength and torsional strength as compared with a solid steel such as round steel, It is an economical cross section steel widely used in the manufacturing structure. Parts and mechanical parts such as steel scaffold for oil drilling.

Use and classification of seamless steel pipes:

Application: Seamless steel pipe is an economic section steel which occupies a very important position in the national economy, and it is an economical section steel and it is used in oil, chemical, boiler, power plant, shipbuilding, machine manufacturing, automobile, aerospace, aerospace, energy, geology It is widely used in construction, etc. Military and other departments

Classification:

According to the shape of the section 1: circular section pipe, section pipe with side view

Depending on the material 2: carbon steel pipe, alloy steel pipe, stainless steel pipe, composite pipe

Depending on the connection method 3: Screw connection pipe, welded pipe

Depending on production mode 4: hot rolling (drawing, top, expanded) tube, cold rolling (pull) tube

Depending on purpose 5: Boiler tube, oil well tube, line tube, structural tube, fertilizer tube ......

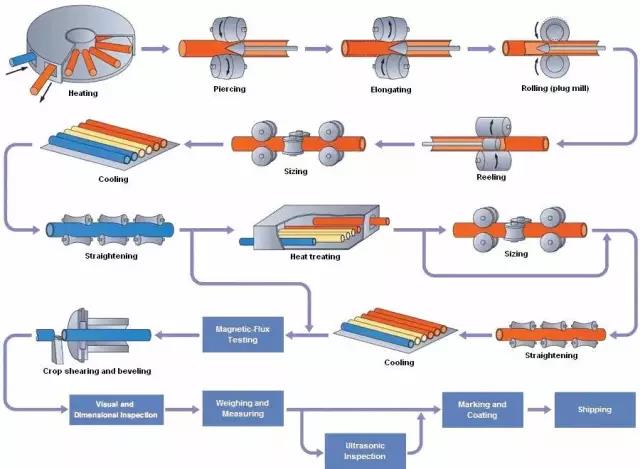

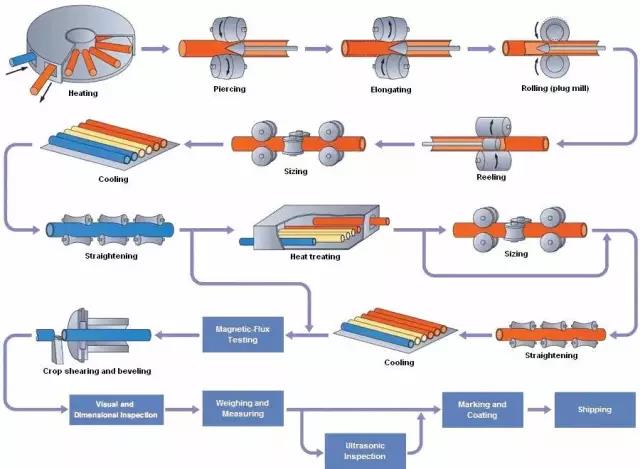

Production process of seamless steel pipe

1 Main manufacturing process of hot rolled seamless steel pipe (main inspection process)

Preparation and inspection of tube blanks → heating of tube billets → piercing → rolling tubes → reheating of waste tubes → fixation (reduction) diameter → heat treatment → correction of finished tubes → finish → inspection (non-destructive, physical and chemical , Taiwan inspection) → storage

2 Cold Rolling (Drawing) Seamless Steel Pipe Main Production Process

Preparation of blank → pickling lubrication → cold rolling (drawing) → heat treatment → correction → finish → inspection

The flow chart of the hot-rolled seamless steel pipe manufacturing process is as follows.